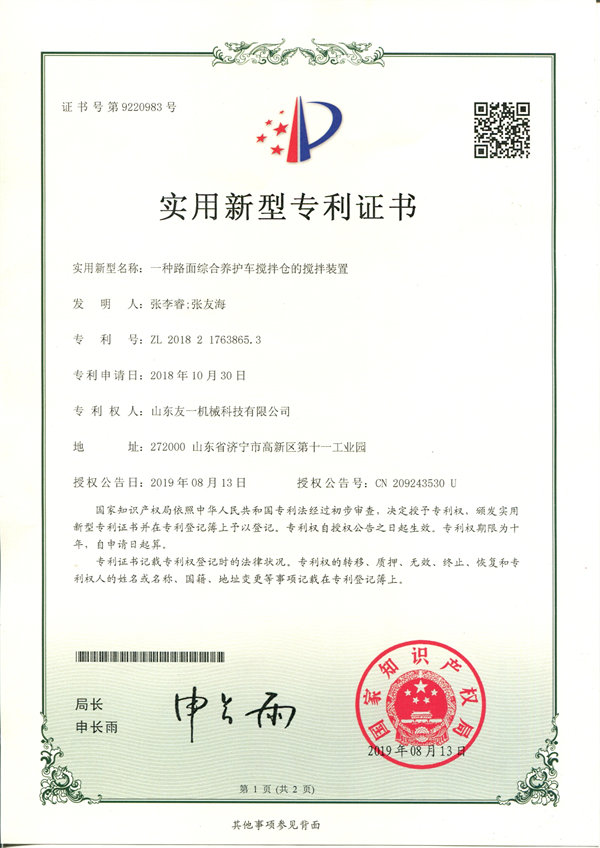

A mixing device for mixing bin of pavement comprehensive maintenance vehicle

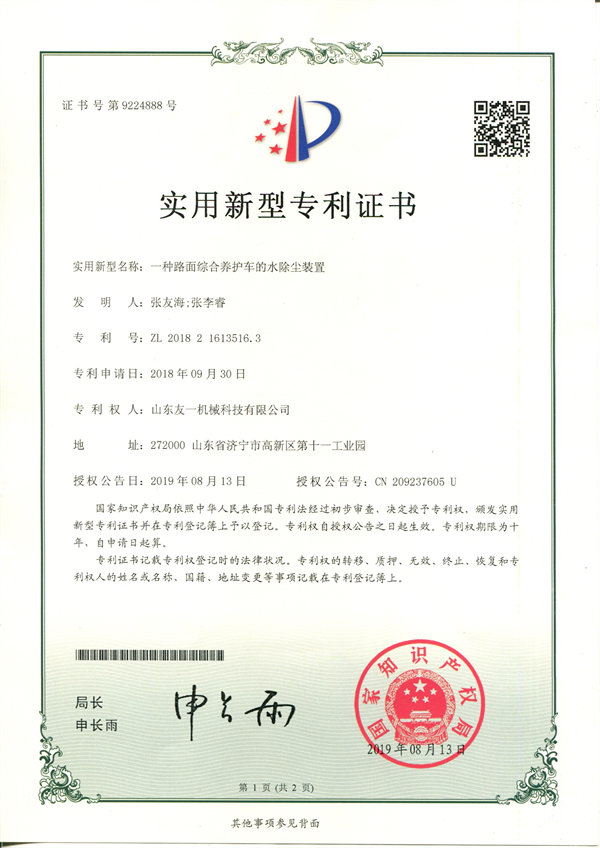

A water dedusting device for pavement comprehensive maintenance vehicle

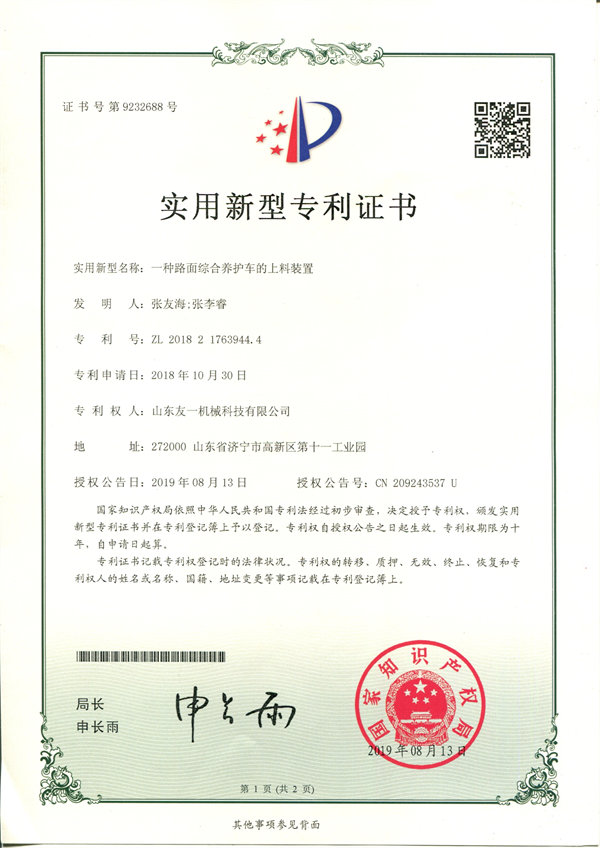

A feeding device for pavement comprehensive maintenance vehicle

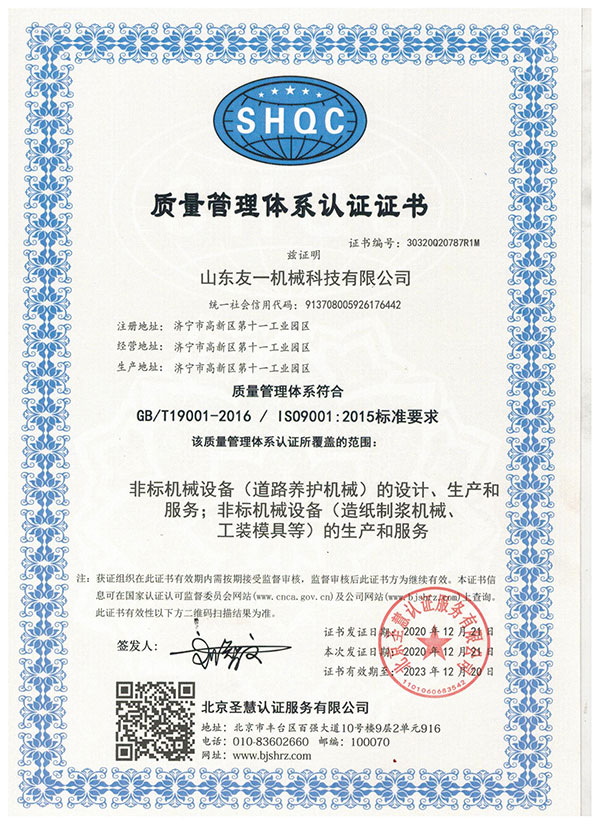

Quality management system certification

Quality oriented and trustworthy enterprise

Service-oriented and trustworthy enterprise

Demonstration enterprise of honest management

Contract abiding and trustworthy enterprise

Enterprise credit registration certificate

Enterprise credit evaluation registration certificate

Environmental management system certification

Computer software copyright truth